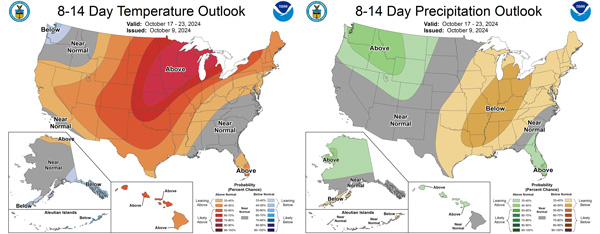

As fall harvest continues across Kansas, many areas of the state are challenged by abnormally dry to severe drought conditions and elevated fire risk. With above-average temperatures and limited to no precipitation expected in the near future (Figure 1.), conditions are perfect for combine fires and quick-moving field fires. Dry crop residues, as well as leaking fuel or oil, can provide ample fuel, and overheated bearings, belts, and chains on harvest equipment can provide ignition during operation.

Figure 1. The temperature and precipitation outlook was issued on October 9, 2024, for the next 8-14 days (October 17-23). Source: Climate Prediction Center.

Awareness and preparation are critical when harvest coincides with excessively dry periods. Before starting your day, always check the weather forecast and make sure others know where you’ll be working that day.

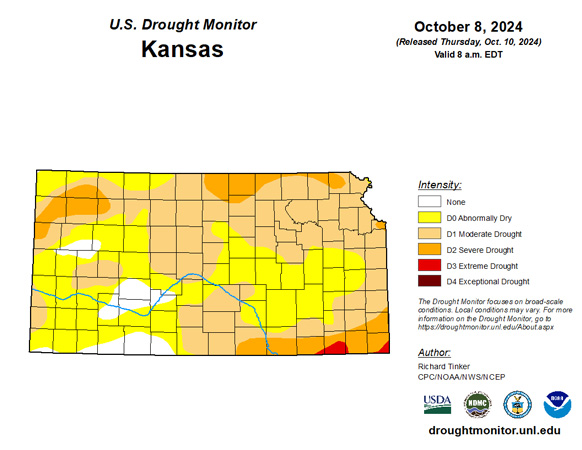

Figure 2. Drought conditions across Kansas as of October 8, 2024. Source: U.S. Drought Monitor.

Know your local fire risk

Several platforms are available to monitor your local fire risk:

- US Drought Monitor. Areas under drought conditions will have very dry vegetation and plant residues on croplands and adjacent natural areas (Figure 2).

- National Weather Service. Know your weather forecast and avoid fieldwork on excessively hot and windy days.

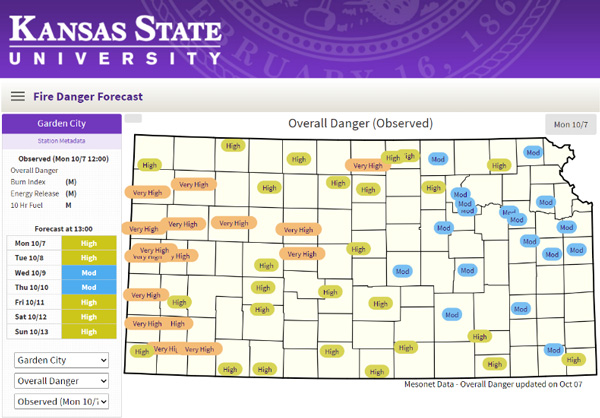

- Kansas Mesonet. Check relative humidity, wind speed, and soil moisture in the area as dry air and dry soil also favor rapid fire spread. Kansas Mesonet’s 7-day fire danger forecast is a great tool for checking out each day during harvest season (Figure 3).

Figure 3. The Kansas Mesonet’s 7-day fire danger forecast (October 7-13). Source: Kansas Mesonet.

Ways to prevent fires at harvest

- Clean harvesters (combines, cotton strippers) regularly, especially around the engine or exhaust. A leaf blower or air compressor is helpful for removing crop residue or debris but power washing may be needed to remove oil or grease that might accelerate a fire.

- Check the machine daily for any overheated bearings or damage in the exhaust system: greasing moving parts, maintaining proper coolant and oil levels, and repairing fuel or oil lines if they appear to leak.

- Use a ground chain attached to the machine’s frame to prevent static charge from igniting dry chaff and residue. The chain should drag in contact with the ground while in the field.

- Check bearings, monitor engine load, and maintain the electrical system. Overheating bearings, excessive engine stress, and overloading circuits can all cause fires.

- Allow engines to cool before refueling whenever possible, and never refuel a harvester while the engine is running.

- Park a hot machine outside and away from buildings. Always allow harvesters to cool down before parking them in sheds.

What to do and have on hand in case of fire

- Have a plan for if a fire occurs, and be sure all employees (hired hands, helpers) know the plan. Your and your people’s safety always comes before saving equipment.

- Always keep a cell phone on hand for any and all emergencies. Regularly charge your phone fully (100%) or at least once daily.

- Have two fully charged ABC fire extinguishers (regularly checked and maintained) on the machine. Keep a 10-pound unit in the cab and a 20-pound unit mounted outside and at ground level.

- Have one fully charged ABC fire extinguisher (regularly checked and maintained) in the tractor, grain cart, and pickup truck. These extinguishers are for the first sign of smoke or a small flame.

- Have a shovel on standby. Though small, they can be used to throw dirt over burning residue.

How to respond if you have a fire

- If safe, move the machine to a harvested area with less standing crop residue that could serve as fuel and spread the fire (Figure 4).

- Turn the engine off to stop the air intake from feeding oxygen to the fire and move a safe distance from the machine.

- Call 911 as soon as possible before trying to extinguish the fire yourself and provide clear directions to your location for emergency services.

- Use the fire extinguisher from a safe distance away. Be careful when opening compartments on the machine, as small fires can flare up with additional oxygen.

- Remember the PASS technique: Pull the pin, Aim the nozzle, Squeeze the trigger, and Sweep across the base of the fire.

- If the fire cannot be extinguished, work to contain the fire to prevent spread through the field.

Figure 4. Machine fires happen fast. If safe, move the machine to a harvested area and call 911 as soon as possible. Photos courtesy of Jay Wisbey, K-State Research & Extension.

Take-home points

- Check the Kansas Mesonet’s 7-day fire danger forecast each day during the harvest season.

- Regularly clean harvesters and monitor bearings, engine load, and the electrical system.

- Have a plan for if a fire occurs, and be sure all employees (hired hands, helpers) know the plan.

- Call 911 as soon as possible before trying to extinguish the fire yourself.

- Remember the PASS technique: Pull the pin, Aim the nozzle, Squeeze the trigger, and Sweep across the base of the fire.

- If the fire cannot be extinguished, work to contain the fire to prevent spread through the field

By taking precautions and preparing for emergencies, we can protect ourselves, our employees (hired hands, helpers), our farms, and our communities. Always prioritize your and your people’s safety over equipment—no piece of machinery is worth risking a life!

Stay aware of the risk and stay safe this harvest season!

Logan Simon, Southwest Area Agronomist

lsimon@ksu.edu

Tina Sullivan, Northeast Area Agronomist

tsullivan@ksu.edu

Christopher “Chip” Redmond, Kansas Mesonet

christopherredmond@ksu.edu