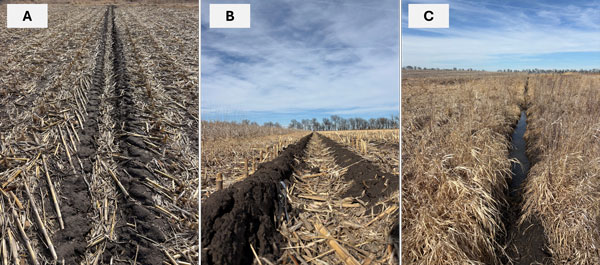

Wheel track maintenance can be a major challenge for many irrigators. Wheel or pivot tracks can be simple “speed bumps” in the field, or they can be severe enough to cause irrigation wear and equipment damage (Figure 1). If severe enough (i.e., deep), wheel tracks can cause wheel and tire damage, slippage of the machine (due to excessive torque on wheel gears), and alteration of the sprinkler spray pattern. Additionally, no one likes having to get a tower unstuck, especially in tall crops like corn. Wheel tracks are bound to happen in every field, every system, but it’s the severity of the wheel tracks that cause concern. Soil type, water applications, and cropping system all play into this complex situation. Sometimes wheel tracks can simply signal too frequent or too heavy applications that can be fixed with proper scheduling. However, there still may be concerns. Here are some potential solutions to mitigate or alter wheel tracks.

Figure 1. This trio of photos illustrates varying levels of wheel track severity. Photo A is the least severe and can be fixed with light tillage or filled in. Photo B may indicate the weight of wheels pushing and sidewalling soil that can progress over the season. Photo C is a more severe case. In this field, a grass stand does not prevent severe wheel tracks from forming. Standing water indicates an infiltration issue and will cause the system to slow down through the track. Photos by Scott Dooley, K-State Extension.

Potential Solution: Soil pressure from wheels

This would be considered changing the weight per square inch (psi) to which the weight is applied. Realistically, we cannot change the weight of the irrigation system; thus, we would need to adjust the tires and wheels.

Larger wheels and tires: Increasing the size would increase the contact surface area and reduce the pressure on the soil. Increasing tire/wheel adds driveline load, requires higher torque, and may increase drive motor and gear box failure. Additionally, larger tires are often more expensive and can increase operating costs (i.e., fuel).

Reduce tire pressure: Lowering tire pressure can increase soil surface contact. However, it also increases sidewall flexing and the potential for cracking, ultimately shortening tire life. Tire pressure should not be lowered beyond the manufacturer’s recommended range.

Additional wheels and tires: Adding a third tire to a tower can increase soil contact and decrease soil pressure. However, most machines are not fitted for this design, thus requiring additional costs to retrofit the system.

Alternative options: These include adding a track system, airless tire options, angled plating, and cambered configurations. Please note that all of this can lead to additional costs and increased wear on the system.

Potential Solution: Soil structure

It is more common to see troubling wheel tracks in fine-textured (clay) soils, as they lose their bearing strength in the presence of water, as compared with sandy soils. Soil conditioners exist on the market, claiming to bind soil particles together. Some products have worked better than others in university research and are highly dependent on product, soil type, irrigation application, and additional factors. The most tested product includes polyacrylamide (PAM) and has been shown to help bind soil particles together to mitigate erosion in furrow irrigation systems, but when used in wheel tracks, it can cause water pooling. UNL, Oregon State, and USDA Idaho have noted PAM working in such a way, but with limited success when used in wheel tracks, as found in a Utah State University trial. Irrigators should use caution and test small quantities for farm utility.

Potential Solution: Modify the irrigation system

Changing sprinkler applicator spacing and height alters the distribution of applied water, directly affecting runoff, wind drift, and evaporative losses, and consequently how water interacts with wheel tracks. Placing applicators closer to the soil surface concentrates water delivery, allowing managers to intentionally avoid applying water near wheel tracks. However, if not properly managed, this approach can increase the risk of surface runoff and create additional management concerns.

Half-circle sprinklers near the towers can be used to direct water away from wheel tracks. While this approach can reduce water accumulation in wheel tracks, poor design or setup can result in yield losses near the wheel paths. Additionally, when the wetted area is reduced (e.g., by half), nozzle size must be adjusted accordingly to avoid over-applying water to the irrigated area.

Boombacks function similarly to half-circle sprinklers by redirecting water away from the direction of travel. A boomback is an offset sprinkler mounted a set distance behind the pivot lateral, allowing water to be applied after the system has already traversed the area. If a single boomback is installed, then the system can only operate in a single travel direction. A double boomback with a reversible valve allows the system to travel both directions. Either option may increase pressure requirements due to the additional piping.

Modifying span pipe drains can be one of the simplest ways to reduce water applied in wheel tracks, particularly when one has been noted to drain excessively. When functioning properly, automatic drains should only release water during system start-up and shutdown, yet they are often overlooked during routine maintenance. We do not recommend removing the automatic drain, but instead connecting it to a hose and teeing it into a pressure regulator so the discharge water is routed through a sprinkler and applied away from the wheel track.

Sprinkler removal can be used in severe situations as it simply eliminates water hitting the wheel track. Yield losses can be associated with this method as the irrigation pattern has been changed entirely.

Potential Solution: Filling and maintaining wheel tracks

In some situations, wheel tracks get so deep that they must be filled. Typically, a pivot track closer will be effective to do this during the off-season. Alternatively, soil can be used by compacting and flattening the track with a terrace blade, road grader, or crowder to limit water pooling and rut formation. If needed, materials such as gravel can be added and are effective, but they can affect field operations, including tillage, nutrient application, and planting, and can reduce the farmable area of a field. Straw has also been used in wheel tracks to add structural support. Each option has tradeoffs to consider, including product cost, trucking, labor, and potential impacts on field operations.

Take-Home Message

Many of these options are viable for most operations, but it comes down to what best fits the field, crop rotation, and budget, as these practices can range from a few hundred dollars per acre to thousands based on field size, machine size, and wheel track severity. Methods are generally categorized as those that decrease the pressure on the wet soil by increasing the contact area with the soil, keep water out of the wheel track, and fill the wheel tracks.

References and supplemental materials

https://waterquality.montana.edu/farm-ranch/irrigation/pam/facts.html

https://extension.usu.edu/crops/research/guide-to-pivot-track-management

https://extensionpubs.unl.edu/publication/g1866/na/html/view

Tina Sullivan, Northeast Area Agronomist

tsullivan@ksu.edu

Daran Rudnick, Professor and Director of Sustainable Irrigation

drudnick@ksu.edu

Jonathan Aguilar, Professor and Irrigation Specialist

jaguilar@ksu.edu

Tags: irrigation equipment