Harvest aids are commonly used in cotton production to prepare the crop for harvest and optimize lint yield and fiber quality. Harvest aid categories include boll openers, defoliants, desiccants, and regrowth inhibitors.

Harvest aid timing

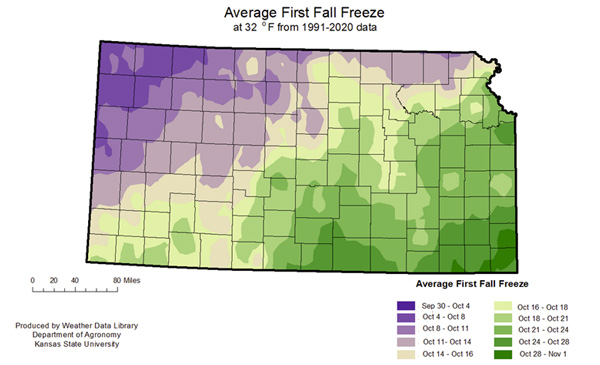

The timing of harvest aid applications relative to crop maturity is essential. Several methods exist to determine crop maturity and defoliation readiness, including counting nodes above the highest cracked boll and the percentage of open bolls. When counting nodes above the highest cracked boll, the standard recommendation is either 4 or 5 nodes above the cracked boll (NACB). However, waiting until 4-5 NACB is often too late in this thermally-limited region, where the first fall freeze of the season typically occurs in mid to late October (Figure 1).

Figure 1. Average first fall freeze dates. Courtesy of the Kansas State Weather Data Library.

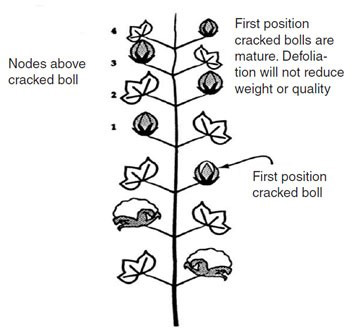

To count NACB, find your top mature boll in the first fruiting position that is just splitting (not fully open), and count the number of mainstem nodes above it to the top of the plant. If that number is 4 or less, you’re ready to go. If the number is greater than 4, any boll above that is likely to be less mature than you would like (ideally).

Figure 2. Determining nodes above cracked boll (NACB). Source: Guthrie, D., Cothren, T., and Snipes, C. 1993. The Art and Science of Defoliation. Cotton Physiology Today Volume 4, No. 7, National Cotton Council, Cordova, TN.

Currently, the most common method for timing harvest-aid applications used in Kansas is based on percentage open bolls. Typically, harvest aids are applied at 60% open bolls (Figure 3). However, Kansas cotton growers have been surprised to see applications at 20% or even 10% open bolls result in no or minimal differences in lint quality. Still, these early harvest aid applications could hurt the cotton seed weight and payment received for cotton seed, often 15 to 20% of total gross returns from a cotton crop. In Kansas, the value of the cottonseed is typically used to cover, at least in part, the cost of ginning, with the remainder paid to the producer, referred to as seed credit.

Figure 3. Open cotton boll. Photo by Logan Simon, K-State Research & Extension.

Immature cotton seeds may have lower seed weights as well as lower oil and protein concentrations. With this in mind, another method for timing harvest aid applications is monitoring the seed maturity of the uppermost harvestable bolls. In this case, the decision to apply harvest aids occurs when the uppermost harvestable bolls have mature seeds (seed coats have turned black) (Figure 3).

Figure 4. Cotton boll with mature seeds (seed coats have turned black). Photo courtesy of Rex Friesen, Southern Kansas Cotton Growers.

Harvest aid products

In addition to timing, cotton producers must decide on harvest-aid product selection and sequence. Several products are available as harvest aids in cotton (Table 1). In Kansas, harvest aids are typically applied in two sequential applications. The most common and least expensive strategy used for rainfed cotton is the application of 32-40 oz/A Prep (Ethephon, a boll opener) with 3-4 oz/A Gramoxone (Paraquat, a desiccant), followed by 16-24 oz/A Gramoxone 10-14 days later. For irrigated cotton, which typically has a denser canopy than rainfed cotton, the most common strategy is the application of 32-40 oz/A Prep with 3 oz/A Folex (S, S, S-Tributyl phosphorotrithioate, a defoliant) followed by 16-24 oz/A Gramoxone 10-14 days later. This strategy is less common for rainfed cotton, primarily due to the increased expense associated with Folex.

Recent research conducted near Mount Hope and Bently evaluated the influence of harvest aid application timing on boll opening defoliation by Prep plus several defoliants. Data are presented in Table 1. The most important factor in determining defoliation and percent open bolls was application timing, with later application associated with greater defoliation and more open bolls. However, there was a trend of less defoliation and fewer open bolls when Aim or Folex were applied compared to Reviton or Sharpen. There were no differences in yield or quality among the treatments evaluated.

Table 1. Cotton percent defoliation 14 days after application of harvest aid treatments at Mount Hope and Bently, KS, in 2023.

|

Product |

|

Application time |

|

|

50% |

75% |

||

|

Rate |

Mount Hope |

||

|

Aim† |

0.2 |

78 |

80 |

|

|

0.4 |

60 |

81 |

|

Folex |

11 |

75 |

86 |

|

Reviton |

0.3 |

85 |

84 |

|

|

0.9 |

80 |

85 |

|

Sharpen |

0.3 |

75 |

90 |

|

|

0.6 |

68 |

93 |

|

|

|||

|

|

|

Bently |

|

|

Aim |

0.2 |

87 |

96 |

|

|

0.4 |

86 |

93 |

|

Folex |

11 |

86 |

97 |

|

Reviton |

0.3 |

96 |

98 |

|

|

0.9 |

95 |

95 |

|

Sharpen |

0.3 |

98 |

99 |

|

|

0.6 |

99 |

99 |

†Aim, carfentrazone; Folex, Tributyl phosphorotrithioate; Reviton, Tiafenacil; Sharpen, Saflufenacil. All treatments included Prep (Ethephon) at 18 oz a.i./acre as a boll opener.

Other considerations for harvest aid applications

- Spray coverage is key, with carrier volume being critically important. Increased carrier volume provides greater coverage for rapid and effective defoliation and boll opening.

- Nozzle tips that produce coarse to medium-fine droplet sizes are recommended for optimum coverage.

- Slower ground speed also typically allows for better coverage and deeper penetration through the crop canopy.

- Most boll opener labels will outline rate suggestions based on temperature ranges. Refer to the label of your specific boll opener selection for details.

The use of trade names is for clarity to readers and does not imply endorsement of a particular product, nor does exclusion imply non-approval. Always consult the herbicide label for the most current use requirements.

Logan Simon, Southwest Area Agronomist, Garden City

lsimon@ksu.edu

Sarah Lancaster, Extension Weed Management Specialist

slancaster@ksu.edu

Lucas De Freitas Granzioli, K-State Weed Science Intern

Tags: cotton harvest aid